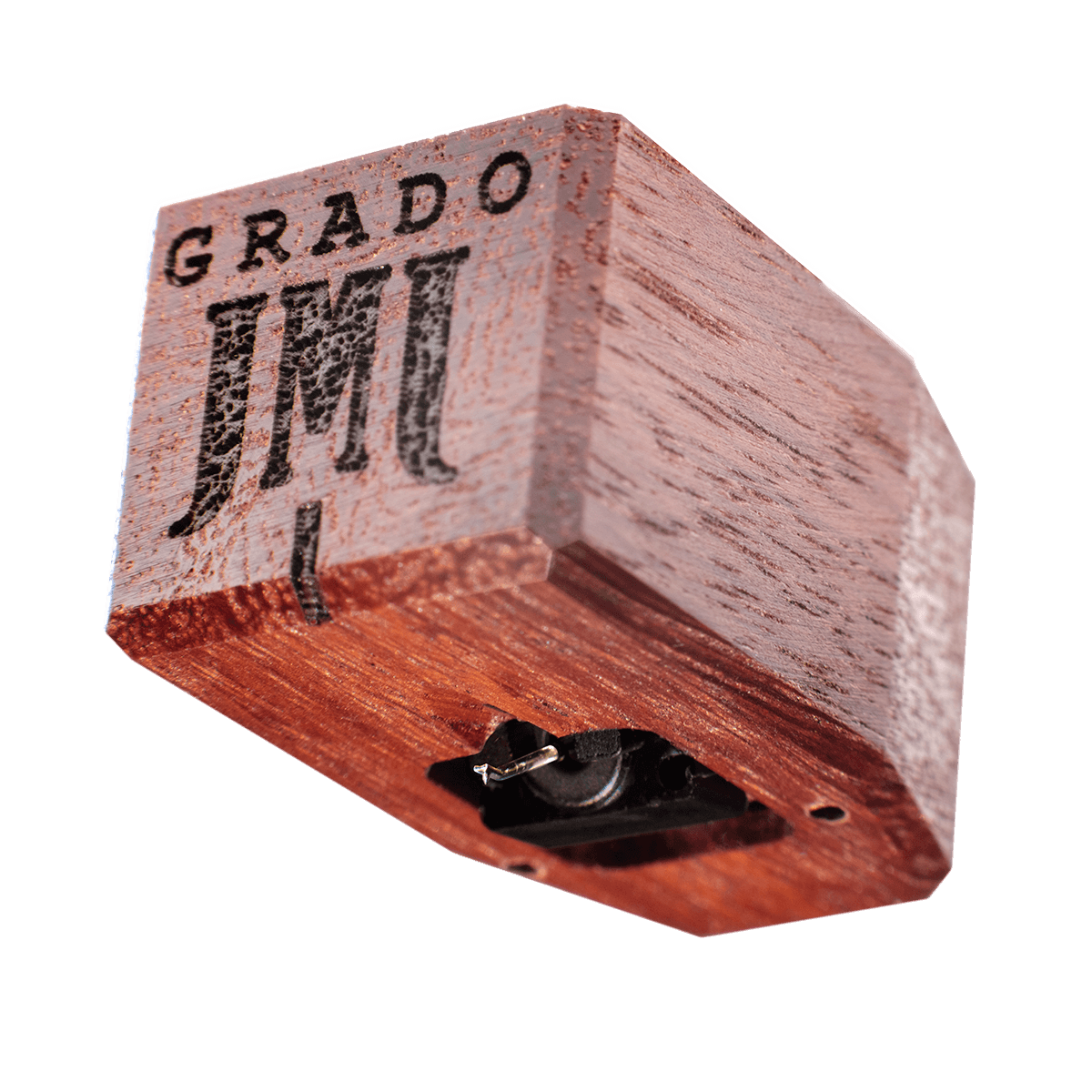

Cured Jarrah For The Cure

Nearing the top of the Timbre Series, the Master3 achieves optimal sonic quality due to an intricate curing process and specialized materials reserved for our best cartridges.

From Here on Out.

On Reserve.

Some practices we reserve for cartridges near the top of the line, and it starts here. To achieve our desired sound, we experimented with multiple longer curing processes that differ from the Opus3, Platinum3, and Sonata3 while using more modified materials. Each Master3 is individually calibrated after being assembled.

Small Necessities.

The Materials

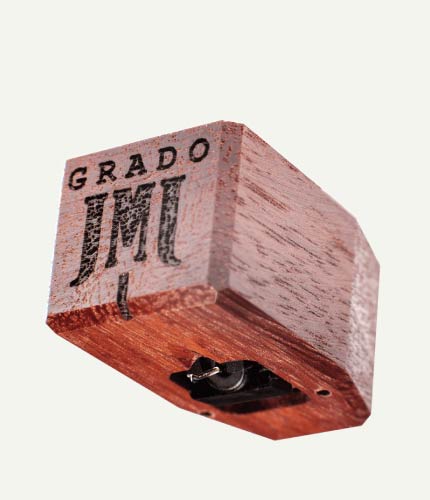

To make the Timbre Series work as a whole, we created a way for Jarrah, diamonds, and a twin magnet system to integrate with our Flux-Bridge™. Unlike the cartridges before it, we modified our five piece OTL cantilever technology to achieve a 5% tip mass reduction over the Prestige Series and use ultra-high purity long crystal (UHPLC) oxygen free copper wire in the coils. The Master3 uses a specially Grado designed nude elliptical diamond.

In the Details.

Extreme Precision

Grado has combined newly developed coil winding techniques with decades-old disciplines. A new two-step shielding process brings not only exact unison between the four coils but an unobstructed path for a cleaner signal. The music is allowed to travel undistorted through the coils, greatly reducing mechanical noise while improving tracking. There is an extreme clarity over the full frequency range, with absolutely no stridency or shrillness. Precisely hand tipped with a diamond, a great amount of care go into each cartridge we assemble.

The Sound of Wood.

House of Jarrah

After the Platinum3 cartridge is crafted, it is then placed inside a Australian Jarrah housing. Jarrah is necessary for the majority of Timbre Series with its ability to produce surgically precise clarity without losing any depth. Through a variation of thermal aging processes, the housing gains the ability to better dampen and control the resonant frequencies.

With Love.

Hand Assembled in Brooklyn

Each Master3 is hand assembled by our team in Brooklyn. Fine tuned for everything from entry-level turntables up to the highest-end stereo systems, the solid mass of the wood helps keep the Master3 steady and producing the Grado signature sound. We started with cartridges on a kitchen table in 1953, and every experience since then has led to the creation of the Master3.

The arrival of a cured mahogany cartridge identical to the one I already owned found me unprepared for the next vaulting leap in my listening education. Within a week of auditioning the 0.5 mv Statement Reference, I began to believe that both my new and vintage vinyl had received a rite of purification, cleansed and made better than new. It was also as though the tiny hairs in my inner ear had been degunked, and in a stroke my hearing was perfectly clear.

Master3

Timbre Series

- Body: Australian Jarrah Wood

- Cantileaver: Machined Boron / Diamond Tip

- Output:

High 4.0mV @5 CMV (45)

Low 1.0mV @5 CMV (45) - Inductance:

High Output 55mH

Low Output 6mH - Resistance:

High Output 660 ohms

Low Output 70 ohms

- Input Load: 10k-47k ohms

- Cartridge Weight: 10 grams

- Tracking Force: 1.6-1.9 grams

- Compliance 20μm/mN

- Channel Separation: Average 30db - 10-30k Hz

- Controlled Frequency Response: 10-60 KHz

- Non-Sensative to Capacitive Load

- Styles: High Output, Low Output, Mono